Without a proper process, your standardized practices are sure to be forgotten. If this is not followed, your products are sure to drop in quality. Production planning is vital for any manufacturing or craft business.Įven basic products need a clear and defined flow to turn them from raw materials into quality goods.

When scheduling production of products what are the key factors to consider? Finding the optimal way to complete orders on time.

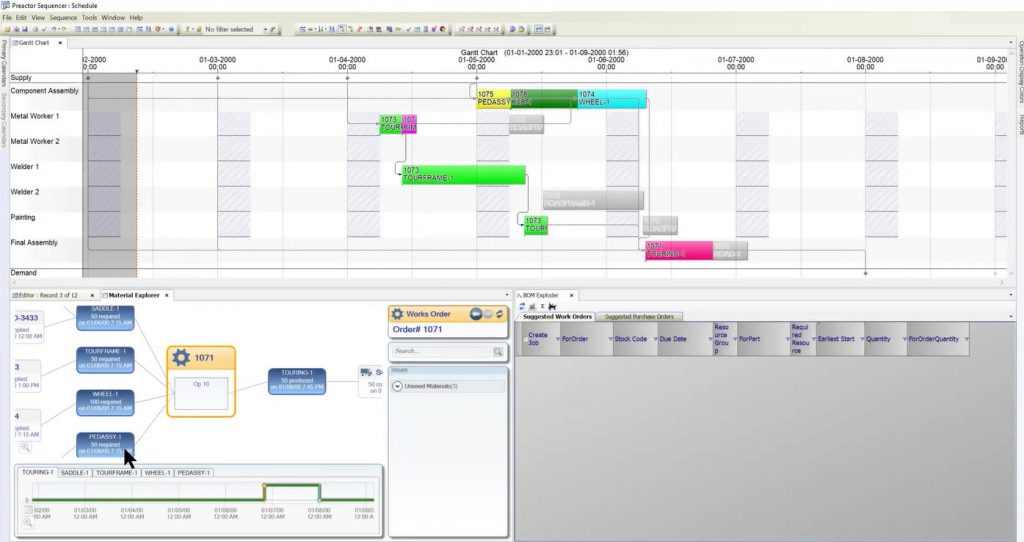

Identifying inefficient spots in the production chain.Thinking ahead - anticipating situations like high demand, shortfall, and bottlenecks.Producing goods in the most logical and straightforward way possible.In general, good production planning involves: Manufacturing process optimization means making sure dead stock and disappointed customers are non-existent. If any part of your production is off, then delays happen. Some may think that you can rush over management or sweep strategy under the rug. It allows you to stay on top of your floor-level management. It saves operation managers time when finding ways to optimize the production flow. Using production planning software helps you break this process down into manageable pieces. Afterward, measures need to be in place that prevents something similar from occurring. This takes time and resources, which could be spent elsewhere. It takes an effective production manager to diagnose and address the causes of bottlenecks. Crew members will get stressed and demoralized while struggling to keep up.Customers will get frustrated with delayed orders.They can cause significant issues in your production flow. This leads to bottlenecks in your production process.īottlenecks are slow spots in your production line. But allow them to continue, then it will grow into a big one. Small inefficiencies may not be noticeable at first. Neglecting your order fulfillment process leads to problems arising sooner or later. The importance of scheduling and production planning processes Having already established your production planning, routing, and scheduling, the next step is the execution stage, when you issue supporting orders or instructions to enable production. ExecutionĮxecution is related to the process of undertaking your production planning and scheduling. This recipe is part of your bill of materials (BOM) and is a cornerstone of your master production schedule (MPS). When a huge order comes in, you don’t have to estimate or guess, as you have “the knowledge” - the recipe for everything your business produces - at your disposal. Production scheduling is the management of these processes to ensure they are completed in a timely and economical fashion. If done correctly, you’ll know at what stage your item is at and which machine, tool, or work center it needs to travel to next. The manufacturing route defines the path from raw materials through to the production of a finished product. Routing, or routing manufacturing, is the route or path to be followed during each step of the manufacturing process. You need to understand how each part of your manufacturing process interacts and works together optimally. Knowing measurements and figures is not enough. Complete production planning involves the accurate tracking of: It is a crucial step in production management and scheduling. Production planning is the process in manufacturing that ensures you have sufficient raw materials, labor, and resources in order to produce finished products to schedule. The four stages of production scheduling are: 1. Four stages of production planning and scheduling This is not robust enough for effective production planning and leaves you few chances to analyze and optimize your processes. On the other side of the scale, there is off-the-shelf software like Excel. This makes them too complex for a business’ needs. The problem is that most of these tools are geared towards large manufacturing businesses. There are many production planning tools available on the market. Even the most straightforward business can get turned around without a solid plan to manage and schedule production. Do this well and watch as every part of your order fulfillment process work together, as it should. It takes solid management with the right production planning and scheduling software. The answer is simple: find the right tools.

0 kommentar(er)

0 kommentar(er)